Ciner Glass’ project in Lommel

As a leading producer of container glass, Ciner Glass intends to set up a greenfield production facility in Western Europe.

The beverage market (incl. beer, wine, mineral water and soft drinks) is growing. There is a low density and even scarcity of container glass production in the area and, currently, most volumes of container glass need to be imported.

Ciner Glass’ team has chosen the strategic location of Kristalpark III in Lommel, Limburg, Flanders, Belgium.

- Long and rich heritage of glass production

- Availability of silica sand, the perfect raw material for high-quality glass, and cullet, allowing to increase the percentage of recycled glass to 75% and to close the loop.

- Closeness to the Port of Antwerp

and big global beverage brands - Availability of renewable (solar and wind) energy

- In a range of 300km potential of customers

This investment would redefine the European container glass market and bring high added value to the Flemish Region.

- Investment of ±€600million

- Creation of ±550 direct and 500 indirect jobs

of which 80% blue-collar in full shifts - Significant reduction of carbon footprint: less raw material and energy in light-weight production process and sustainable transport

- Innovation and knowledge development

- Internalisation of container glass value chain within Flemish Region

Facts & figures

Ciner Group

- Large international family group; one of the largest corporations in Turkey

active in glass, chemicals, energy, mining, media, maritime, tourism … - Established in 1978

- Headquartered in Istanbul, Turkey

- Founder and Chairman: Mr. Turgay Ciner

- Employees: > 10,000 worldwide

- Annual turnover: > €3 billion

Ciner Glass

- Holding company for Ciner Group’s global container glass activities

supplying bottles to the beer, wine, soft drink and mineral water market - Established in 2011

- Headquartered in London, UK

- Chair: Mrs. Didem Ciner

- CEO: Mr. Gokhan Sen

- Current facilities: Bilecik Bozüyük, Turkey

- Total operating furnaces: 2 (and 3rd furnace currently being built)

- Total production capacity: 1,000 gross ton/day

- Daily net production: 4.5 million bottles/day (200 g)

- Future investments: Wales, Belgium, …

- Employees: ±560

- Annual turnover: > €100 million

Ciner Glass Belgium NV

- Established on 21 August 2020

- Headquartered (preliminary) at Noordlink, Lommel, Limburg, Flanders, Belgium

Ciner Glass’ project in Lommel

- Location: Kristalpark III ( Marie Popelinstraat 125), Lommel, Limburg, Flanders, Belgium

- Land area required: 200,000 m² (20ha) (for 2 furnaces)

- Building area: 130.000 m² (13ha) (construction area)

- Total investment: ±€600 million

- Total operating furnaces: 2

- Total production capacity: 7 million bottles/day or 1,300 ton/day or 650 ton/day/furnace or 2.5 billion bottles/year or 474,500 ton/year

- Net production: ±3 million bottles/day or 2,200 pallets/day or ±2.35 billion bottles/year [(180 g)]

- Warehouse capacity: ±203 million bottles or 55,000-65,000 pallets

- Raw materials: 1,462 ton/day or 553,169 ton/year

- Electricity: 20 MW

- Natural gas: 6,500 Sm³/hour

- Ground water extraction: ±413 m³/day or 164,770 m³/year (and max. 600 m³/day)

- Turnover: ±€160 million

- Total direct job creation: ±550

(+/- 400 after finalisation of production line 1; 550 after finalisation after production line 2)- 80% blue-collar

- 20% white-collar

- Total estimated indirect job creation: ±500

Q&A Ciner Glass’ project in Lommel

Why does Ciner Glass want to build a container glass production facility in Lommel? Why did the company choose Belgium/Limburg/Lommel for the construction of its new facility?

- The choice of Lommel and Flanders seems self-evident. The proximity to major industries at the heart of the European economy, the central location at the crossroads of key transport routes, access to essential raw materials, and the availability of knowledge and labour force make this region the perfect choice for this ambitious project.

- Long and rich heritage of glass production

- Availability of silica sand, the perfect raw material for high-quality glass,

and cullet, allowing to increase the percentage of recycled glass to 75% and to close the loop. - Closeness to customers (big global beverage brands such as AB InBev, Coca-Cola and Heineken) and end users

- Low density and even scarcity of container glass production in the area; high volumes of imported container glass

- Closeness to the port of Antwerp

- Availability of renewable (solar and wind) energy

What is Ciner Glass intending to build in Lommel?

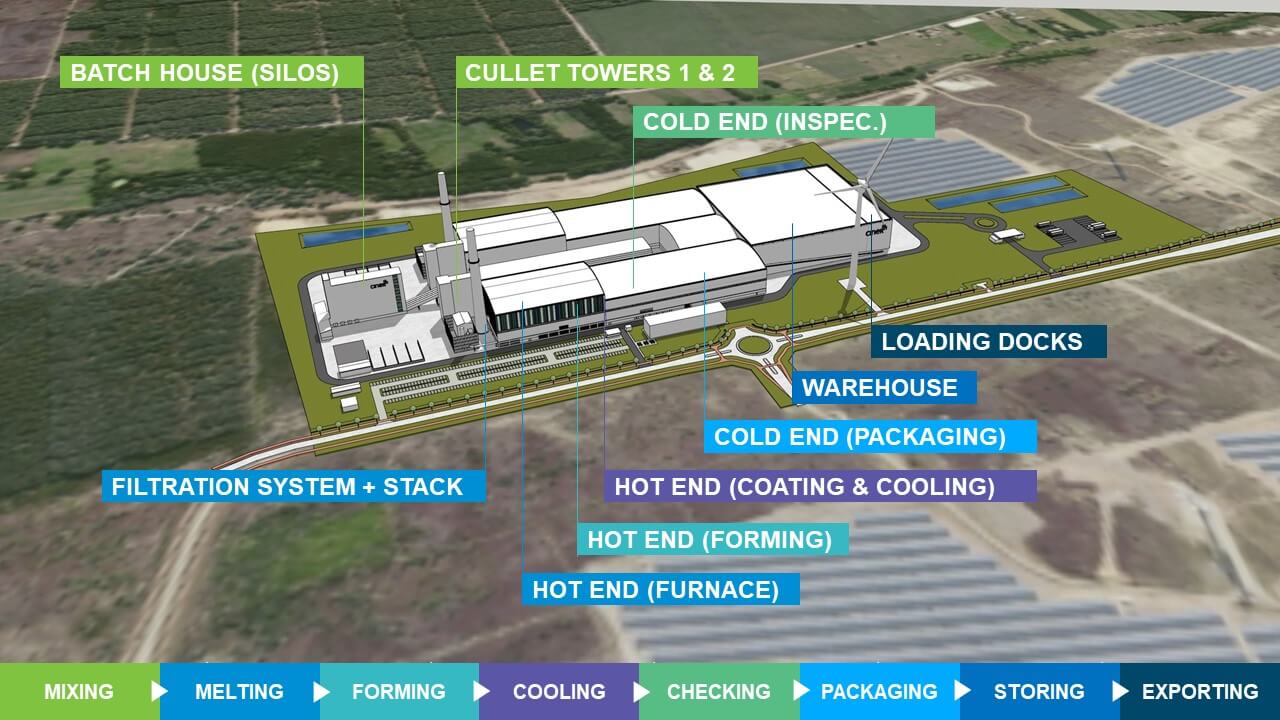

- As a leading producer of container glass, Ciner Glass intends to set up a greenfield production facility in Lommel. The facility would consist of two glass manufacturing furnaces, which will be realized in two phases, as well as warehouses for storing raw materials, waste and finished products.

- The site will also include an administrative building, car and truck parking spaces, rainwater infiltration basins and utility facilities (including a high-voltage room and a natural gas relaxation station).

How big is this investment?

- With an amount of 600 million euros, Ciner Glass’s investment is one of the most substantial in the region in recent years, both in terms of size and scale as well as employment. With a strong focus on ecology and sustainability.

How many jobs will be created with this investment?

- The project would create about 550 direct jobs on a shift basis split between 80% blue-collar and 20% white-collar jobs and 500 indirect jobs.

- The project is expected to have a significant impact on reducing unemployment and establishing an extensive new supply chain of local and regional businesses.

- This production facility constitutes a major investment that would benefit Lommel, the Limburg province and the Flemish Region for decades and generations to come.

Is specific training required to work in a glass factory?

- There is a need for in-depth and thorough training for the new employees at the facility in Lommel. Off course, staff with previous experience in the glass industry would be nice to have but is not needed. We will train the hundreds of people we needed from the local area.

- Large numbers of our manufacturing teams will be trained at the Turkish plant prior to them working at the new plant in Belgium.

- The knowledge that will be built up in Flanders through this extensive training programme is substantial. The project will also put Flanders on the map for the first time as a knowledge centre in the field of glass packaging production.

How will employees of the Lommel-based production facility be remunerated?

- Salaries of Ciner Glass’ Lommel-based employees would be in line with local and sectoral standards in Belgium.

How big is the factory’s ecological footprint and how will Ciner Glass handle the sustainability challenges?

- Ciner Glass is committed to drastically and swiftly reducing its ecological footprint by providing customers with high-quality container glass that is not only lighter but also produced with minimal energy and resource input. Glass can be recycled indefinitely and is environmentally friendly.

- In Lommel, Ciner Glass aims to use 75% recycled glass, which can reduce energy consumption by at least 20% because recycled glass melts at a lower temperature.

- Moreover, the company is innovating by reducing the weight of glass bottles by 10%, resulting in a significant decrease in resource use and CO2 emissions during transport. This weight reduction, combined with local production, will result in an annual CO2 reduction of nearly 29,000 tonnes, significantly shrinking both our ecological footprint and that of our customers.

How is this project being funded?

- The project will be funded by the Ciner Group, an investment to meet the growing demand for glass containers in the European market.

When will the construction start and how long will it take?

- The groundbreaking ceremony was made in November 2023. The preliminary works are nearing completion. Construction will begin in April 2024. The first furnace (F1) will be operational in the third quarter of 2025.

- Construction of the second furnace (F2) is scheduled for the fourth quarter of 2025 and will be operational in the fiscal year 2026. This means that the full production facility will be operational by 2027.

What is the recruitment plan?

We have started recruiting at the start of 2024 with some supporting employees, e.g. engineers, HR, IT, …

We will start recruitment for the first blue collar profiles by end of summer 2024. We will work together with 4 preferred suppliers: StartPeople, Unique Interim, Agilitas en Itzu Jobs.

What kind of profiles will we recruit

- Proces-operator

- Procuctie-operator

- Kwaliteit-operator

- Heftruckchauffeur

- Technieker mechanisch onderhoud

- Technieker electrisch onderhoud

- Teamleaders

- Engineers (electrisch, mechanisch, warehouse, quality, chemical, …)

- Ondersteunende functies zoals HR, finance, IT, aankoop, supply chain, sales

How to apply

Soon, you can see all our vacancies and reach out to us via our career page on our website:

Working times

Of course we are not working our production hours yet. However, please keep in mind that our production will run full shifts throughout the year. For all days off, you need to put vacantion in.

For Blue collars working in full shifts, we probably will be working 5 shifts from Monday till Sunday in an alternating scenario, with equal numbers of morning/noon/night. If you are working in full shifts a shift allowance will be paid.